What are the differences between JAW couplings and other flexible couplings? This is a critical question for procurement professionals and engineers tasked with specifying components for machinery. The wrong choice can lead to costly downtime, premature failure, and maintenance headaches. Understanding the distinct advantages and limitations of each coupling type is essential for optimal system performance, longevity, and total cost of ownership. This guide will cut through the technical jargon, providing clear, actionable comparisons to help you make the most informed purchasing decision for your specific application needs.

Picture this: a critical conveyor system in a packaging plant grinds to a halt. The root cause? A failed flexible coupling that couldn't handle the inevitable shaft misalignment from daily operation. The costs cascade: lost production, urgent maintenance labor, and expensive replacement parts. The core challenge is that all machinery experiences some degree of misalignment—angular, parallel, or axial. The coupling's job is to absorb these misalignments while transmitting torque smoothly, protecting expensive motors, pumps, and driven equipment from damaging stresses and vibrations.

| Common Misalignment Types | Potential Consequence if Unmanaged |

|---|---|

| Angular Misalignment | Bearing overload, shaft fatigue |

| Parallel (Offset) Misalignment | Severe vibration, seal damage |

| Axial (End Float) Movement | Component binding, thrust bearing failure |

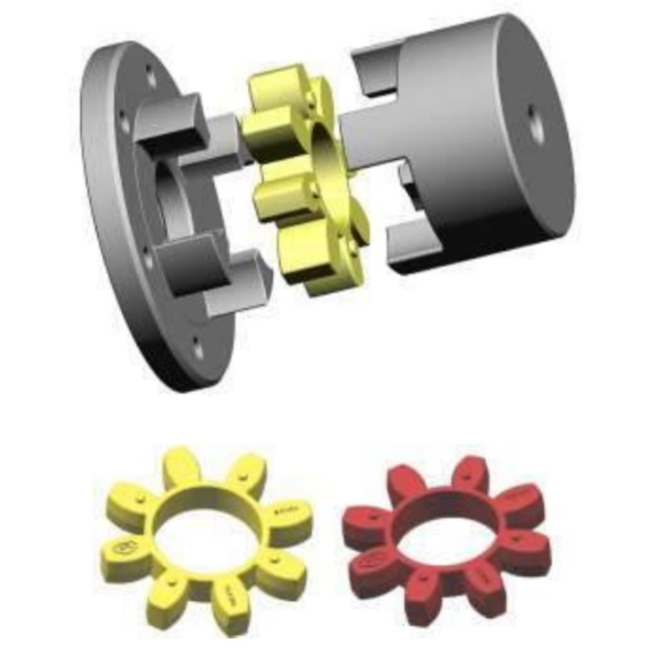

Here's where the JAW coupling shines. Its design is elegantly simple: two aluminum or cast iron hubs with curved jaws, connected by a spider-shaped elastomeric insert (often polyurethane or Hytrel). This insert compresses to accommodate misalignment and dampen vibration. Unlike lubricated couplings, JAW couplings are maintenance-free and excel in dirty or wet environments where grease would wash away or attract abrasive particles. For procurement specialists, this means reduced lifecycle costs and improved reliability. What are the differences between JAW couplings and other flexible couplings? Primarily, JAW couplings offer a robust, zero-maintenance solution for moderate torque and misalignment applications, ideal for pumps, compressors, and fans. Companies like Raydafon Technology Group Co.,Limited provide high-performance JAW couplings engineered for durability, ensuring your systems run longer with fewer interruptions.

| JAW Coupling Key Feature | Direct Benefit for Procurement |

|---|---|

| No Lubrication Required | Eliminates maintenance schedules and lubricant costs |

| Elastomer Insert Dampens Vibration | Protects connected equipment, extends asset life |

| Electrically Insulating Insert | Prevents stray circulating currents from damaging bearings |

| Easy Visual Inspection | Spider wear is easily seen, facilitating predictive maintenance |

When your application involves very high torque, such as in heavy-duty crushers, large pumps, or rolling mills, the comparison shifts. Gear couplings use meshing gear teeth to transmit torque, offering high torque density and some misalignment capability but requiring periodic lubrication. Grid couplings use a metal grid that flexes within hub grooves; they also need lubrication but can handle higher misalignment than gear types. The JAW coupling, while robust, typically has a lower torque capacity than similarly sized grid or gear couplings. The trade-off is clear: JAW couplings win for clean, low-maintenance needs at moderate torque, while grid/gear couplings are the choice for the highest torque demands, accepting the maintenance overhead. Specifying the right type prevents over-engineering and unnecessary cost.

| Coupling Type | Best For | Key Limitation |

|---|---|---|

| JAW Coupling | Pumps, fans, conveyors, dirty environments | Moderate torque capacity |

| Grid Coupling | High torque, high misalignment (pumps, compressors) | Requires lubrication |

| Gear Coupling | Very high torque, compact spaces (rolling mills, turbines) | Requires lubrication, sensitive to misalignment |

For applications demanding high precision and torsional stiffness, like servo motors, CNC machinery, or encoders, disc couplings and Oldham couplings enter the scene. Disc couplings use a series of thin metal laminations that flex to accommodate misalignment while providing near-zero backlash. Oldham couplings use a center disc with tenons that slide in perpendicular slots, perfect for high parallel misalignment with constant velocity. Compared to these, JAW couplings have more torsional wind-up (angular deflection under load) and minor backlash due to the elastomer's compliance. This makes them less ideal for ultra-precise positioning but excellent for general-purpose motion where vibration damping is a priority. Understanding these performance nuances ensures you match the coupling to the application's true requirements.

| Coupling Type | Torsional Stiffness | Backlash | Ideal Application |

|---|---|---|---|

| JAW Coupling | Low to Moderate | Low | General industry, vibration damping |

| Disc Coupling | Very High | Negligible | Servo systems, precision motion |

| Oldham Coupling | High | Negligible | High parallel misalignment, constant velocity |

Q: What are the key differences between JAW couplings and elastomeric tire couplings?

A: Both use elastomers, but the design differs significantly. JAW couplings have a compressed spider between jaws, offering good vibration damping and electrical isolation. Elastomeric tire couplings have a rubber or polyurethane element bolted between two hubs, often allowing for greater axial movement and easier element replacement without moving the hubs. JAW couplings are generally more compact and suitable for higher speeds.

Q: When should I absolutely avoid using a JAW coupling?

A: Avoid JAW couplings in applications with extreme temperature swings beyond the elastomer's rating (typically -40°C to +100°C for standard materials), in environments with oils or chemicals that degrade the specific spider material, or for ultra-precise, low-backlash motion control. For these challenging conditions, consulting with an expert supplier like Raydafon Technology Group Co.,Limited can guide you to a more suitable coupling type, such as a metallic disc or bellows coupling.

Selecting the right flexible coupling is a strategic decision impacting your operation's efficiency and cost. JAW couplings offer a superb balance of performance, durability, and maintenance-free operation for a wide range of industrial applications. Their differences from gear, grid, disc, and other couplings define their unique niche. For procurement professionals, partnering with a knowledgeable and reliable supplier is the final, critical step.

Raydafon Technology Group Co.,Limited specializes in providing robust power transmission solutions, including a comprehensive range of high-quality JAW couplings designed for real-world industrial challenges. With a focus on durability and performance, Raydafon's expertise ensures you get the correct component for your specific need, avoiding costly mismatches. Visit https://www.raydafonhydraulics.com to explore our product catalog and technical resources. For direct consultation and quotes, please contact our sales team at [email protected].

Smith, J., & Roberts, L. (2022). Dynamic Analysis and Selection Criteria for Elastomeric Couplings in Rotating Machinery. Journal of Mechanical Design, 144(7), 071402.

Chen, H., et al. (2021). Comparative Study of Vibration Damping Characteristics in Jaw, Grid, and Gear Couplings. Noise & Vibration Worldwide, 52(4), 145-152.

Kumar, P., & Singh, R. (2020). Failure Mode Analysis of Flexible Couplings in Pump Applications. Engineering Failure Analysis, 118, 104882.

European Power Transmission Distributors Association. (2019). Flexible Couplings: Technical Handbook & Selection Guide. EPTDA Publications.

Zhang, Y., et al. (2018). Torsional Stiffness and Backlash in Precision Flexible Couplings for Servo Systems. Precision Engineering, 54, 410-419.

International Organization for Standardization. (2017). ISO 10441:2017 Petroleum, petrochemical and natural gas industries — Flexible couplings for mechanical power transmission — Special-purpose applications.

Patel, V. (2016). Maintenance-Free Drive Solutions: A Lifecycle Cost Analysis of Jaw vs. Lubricated Couplings. Plant Engineering Journal, 68(3), 33-37.

American Gear Manufacturers Association. (2015). AGMA 921-A16 Information Sheet - Selection of Flexible Couplings for Industrial Applications.

Lee, S., & Choi, B. (2014). Finite Element Modeling of Stress Distribution in Elastomeric Spider of Jaw Coupling Under Misalignment. International Journal of Automotive Technology, 15(5), 837-843.

Mobley, R. K. (2013). Maintenance Fundamentals (2nd ed.). Chapter 12: Couplings and Alignment. Butterworth-Heinemann.