Raydafon Technology Group Co.,Limited has long been committed to management innovation and model innovation, actively exploring the path of enterprise informatization and digitalization, and taking the road of intelligent transformation with deep integration of manufacturing and the Internet. It has successively passed ISO9001 quality management system, IS014001 environmental system, OHSAS18001 occupational health and safety system certification, two-in-one management system assessment and DCMM data management capability maturity level assessment. The digital workshop built in 2019 was rated as a digital workshop in Zhejiang Province. From 2020 to 2021, the two-year construction period of the hydraulic motor smart factory project created the first automated, lean and intelligent "smart factory" in the hydraulic industry, making personnel productivity and batch product stability, new product development cycle, enterprise operating costs and other indicators achieve industry leadership. In 2022, the digital workshop for flexible processing of cycloidal motors was built, which passed the acceptance and was put into use in 2023, further promoting the upgrading of various business models and improving the company's management and operation capabilities. Hydraulic motors have been highly praised by the market for their small size, high torque and high safety. The domestic market share ranks among the top, accounting for nearly 61% of the market in Zhejiang Province. At the same time, the company actively explores the international market, and its products are exported to more than 80 countries and regions including Germany, the United Kingdom, Italy, the United States, Canada, Brazil, Russia, South Korea, etc. EVER POWER uses ingenuity to create excellent quality, takes it as its mission to create a national brand, and becomes a leader in the hydraulic ecology!

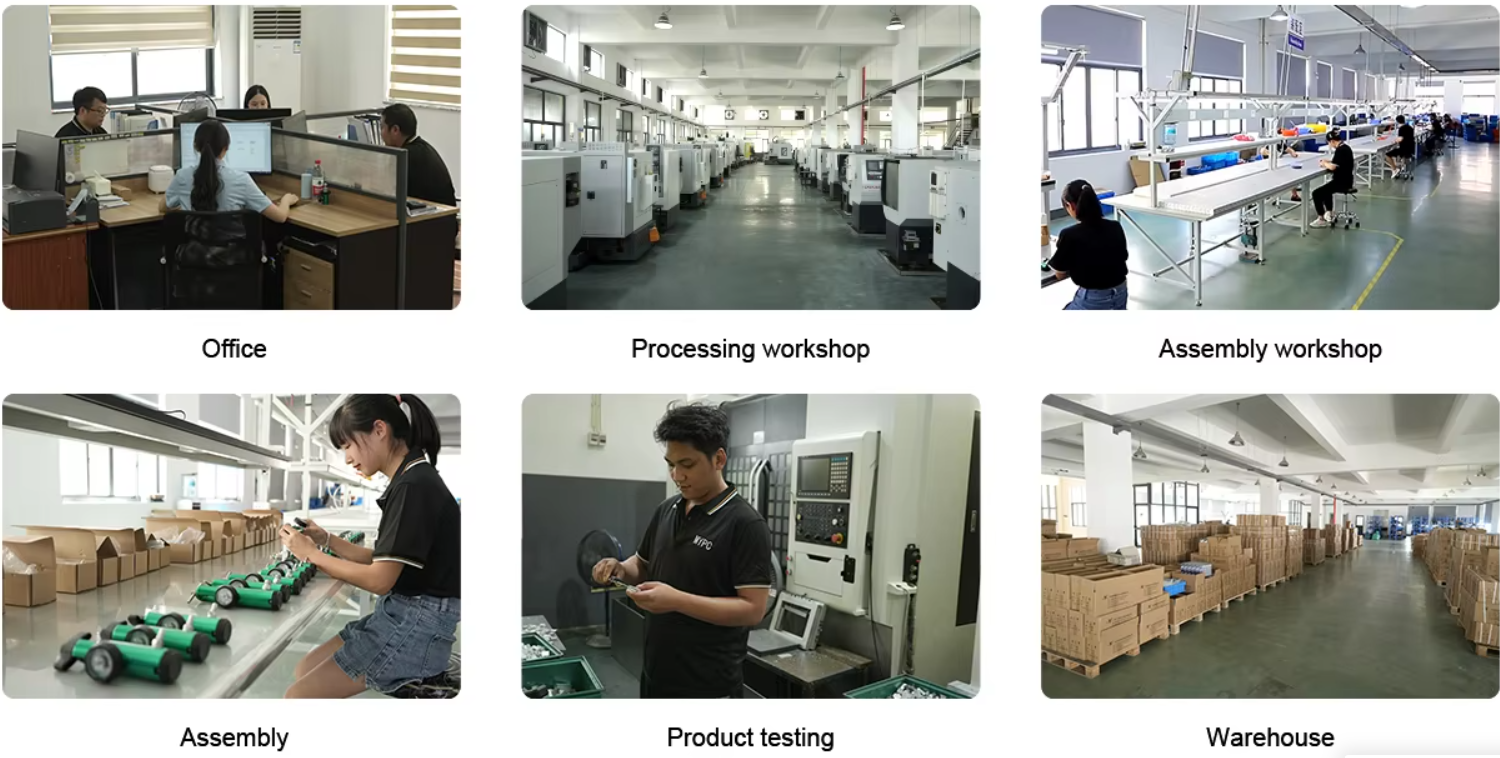

Our company has invested a total of 81 equipment, 39 machining centers, and 36 CNC machine tools in the production line, including 33 imported equipment, for the production and processing of a series of precision parts and accessories for the company, achieving automated production, reducing labor intensity and improving production efficiency, merging processes, and shortening the length of the production line. The equipment is mainly imported to improve the product assurance capability and market competitiveness of the entire production line.

|

For more details, please click here to contact us!

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

FOR MORE DETAIL, PLEASE CONTACT US.

|