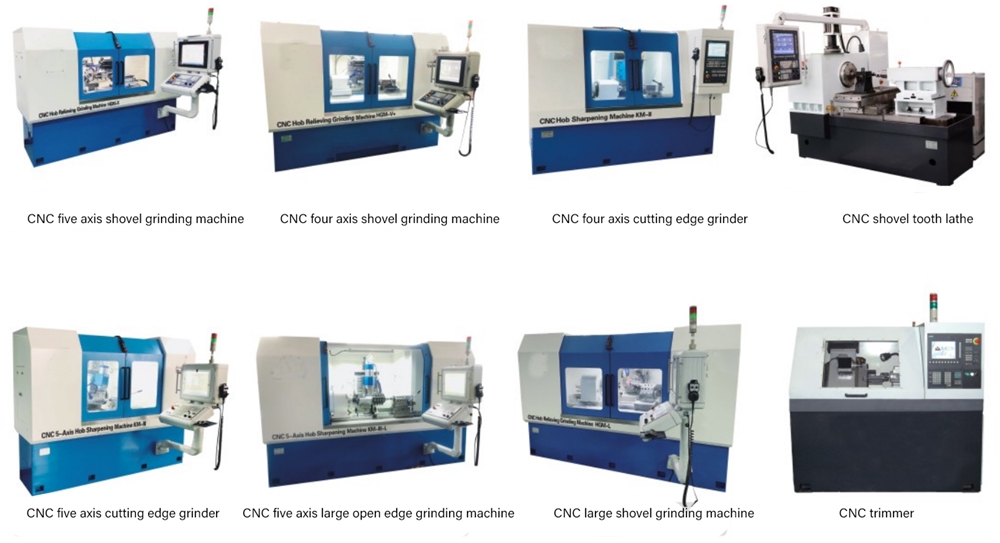

lt is composed of hobbing machine with chamfering station, shaving machine, automatic loading and unloading, automatic oilslitter, automatic sampling table and truss machanical arm and so on automatic equipments, it can finish complete all the gearmaking process before hot treatment by free combination according to customer requirements.