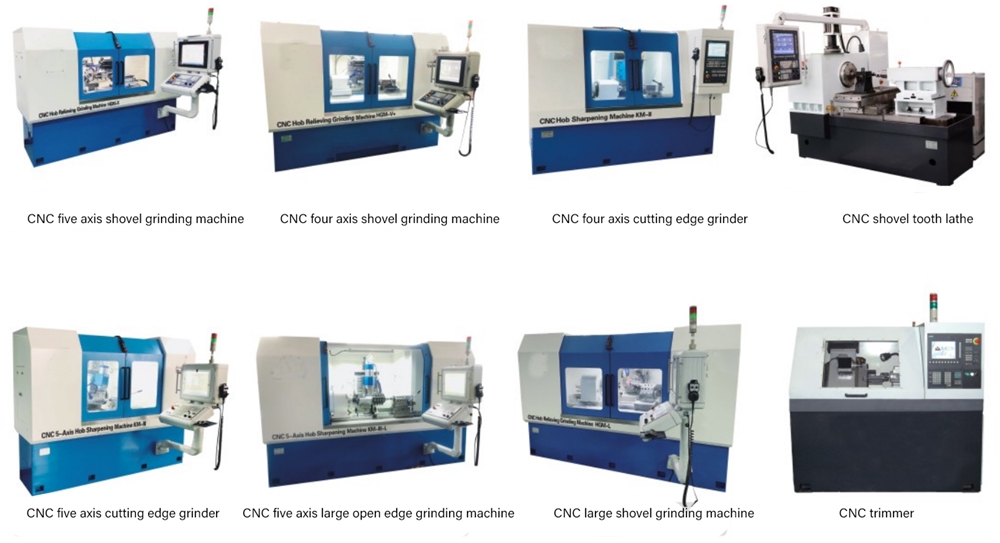

A razor grinding machine is a specialized machine used for the sharpening and grinding of razor blades. It is designed to restore

the cutting edge of razor blades, ensuring they remain sharp and effective for use. Razor grinding machines are commonly used in

the manufacturing or regrinding processes of various types of razors, including straight razors, safety razors, and disposable

razors.