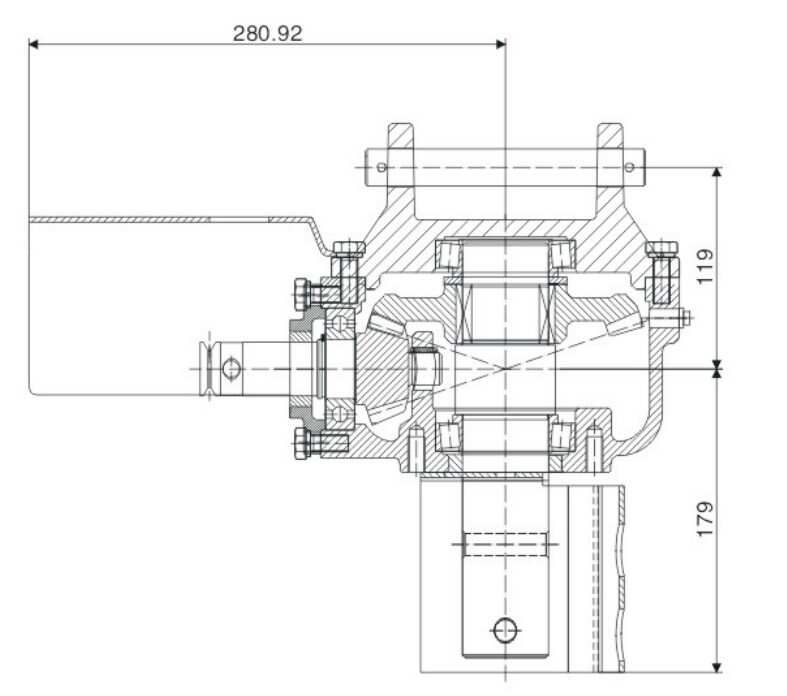

ITEM | EP-650PHD |

Ratio | 2.92:1 |

Teeth | 13/38 |

Module | 4.25 |

Power(HP) | 30 |

Rated lnput | 540 rpm |

lnput/Output Description | Optic axis |

Weight(N.W) | 24.1 Kg |

Click here for more details! |

Please click on the photos below to visit their websites.

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China