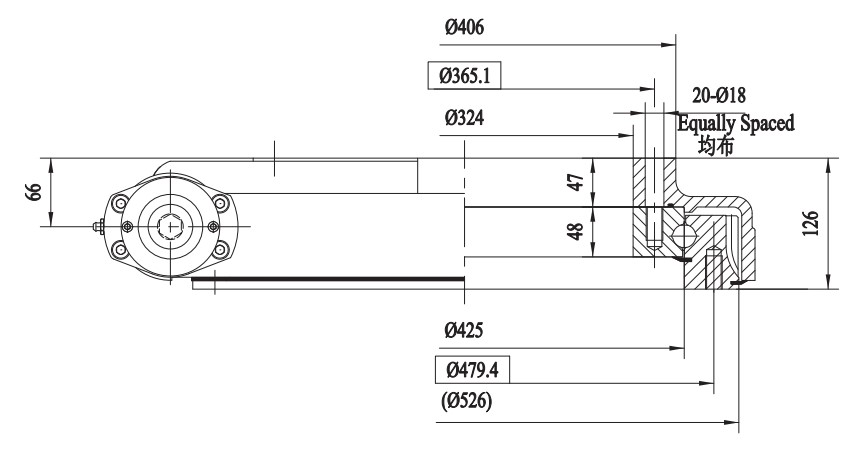

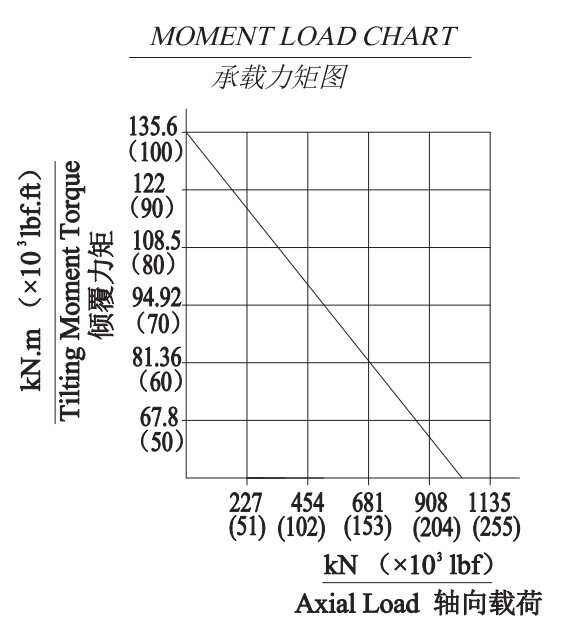

Output torque | Lifting moment torque | Holding torque | Axial load | Radial load | Ratio | Backlash | Weight |

10 KN.M | 135.6 KN.M | 73 KN.M | 980KN | 400 KN | 102:1 | ≤0.15° | 106kg |

7400 LBF.FT | 100*10³ LBF.FT | 53.9*10³ LBF.FT | 220*10³ LBF | 89.9*10³ LBF |

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China