The 1500 heavy-duty three-point pile excavator is a high-quality and durable tool for digging and drilling holes in harsh soil conditions, and is used for construction and agricultural purposes. It is designed with strong and durable steel frame, which can withstand even in the worst terrain. After drilling, the excavator adopts a 9-inch auger with replaceable blade, which is easy to excavate and has durable performance. The auger is also available in various sizes to adapt to different hole sizes. The three-point quick coupling device is designed to provide stable and convenient connection for most tractors, making it easy to operate. In addition, the transmission driven by PTO ensures smooth and easy operation. In general, the 1500 heavy-duty three-point pile hole excavator is the best choice for those who need reliable and powerful tools to dig pile holes quickly and efficiently.

Specification of 1500 heavy three-point pillar excavator

-Tractors rated up to 75 hp

-Series 4 driveline

-Ultra-heavy gearbox, 3:1 reduction ratio

-2 "output shaft with double 1/2" bolt holes for auger attachment

-Select a combination of up to 5 heavy-duty augers

-For tractors of category 1 and 2

-Super-heavy steel suspender

-Backed by our 6-month warranty and excellent customer service

1500 heavy-duty three-point hole digger for sale

Model | Model 400 Compact | Model 650 Standard Duty | Model 1000 Heavy Duty | Model 1500 Extra Heavy Duty |

SKU | 24-0361 | 24-0362 | 24-0318 | 24-0337 |

Category | 0 & 1 | 1 | 1 | 1 & 2 |

Boom Length | 56" | 60" | 72" | 72" |

Tubing Diameter | 2-7/8" | 2-7/8" | 2-7/8" | 3-1/4" |

Draw Pin Width | 20" | 27" | 27" | 32-1/2" |

Drive ine | Series 1 | Series 1 | Series 4 | Series 4 |

Gearbox | 2.9:1 | 2.9:1 | 2.9:1 | 3.18:1 |

Auger Diameters | 6", 9", 12" (3' lengths) | 6", 9", 12" | 6", 9", 12", 18", 24" | 6", 9", 12", 18", 24" |

Weight | 150 bs | 160 bs | 200 bs | 235 bs |

SKU | 24-0361 | 24-0362 | 24-0318 | 24-0337 |

Features | 4 Positions | 3 Positions | 4 Positions | 4 Positions |

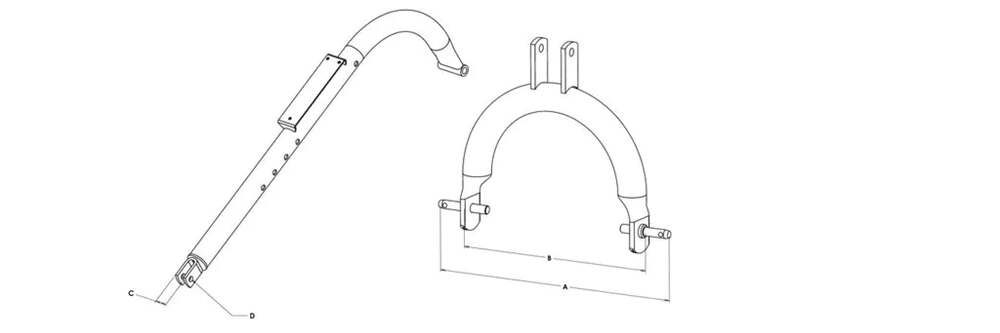

Model # / CAT | A(in) Lower Hitch Point Spread -Max | B(in) Lower Hitch Point Spread -Min | C(in) Clevis/ Ball Joint Outside Width | D(in) Upper Hitch Point Pin Dia |

Model 400 / CAT 0, Sub Compact | 26-3/8 | 20-7/8 | 1.75 | 0.75 |

Model 650 / CAT 1 | 33-1/2 | 28 | 1-5/8 | 1.0 |

Model 1000 / CAT 1 | 32-3/8 | 26-7/8 | 1-5/16 | 0.75 |

Model 1500 / CAT 1 & 2 | 38-3/8 | 32-7/8 | 1-5/16 | 0.75 |

Grinding Workshop

CNC Teeth Machine

CNC Lathe Workshop

Figuring Center

CNC Workshop

Heat Treatment Machine

3D Measurement Machinery

Gear Teeth Profile Test Machines

Heat Treatment Workshop

Tooth Profile Workshop

Low carbon steel, C45, 20CrMnTi, 42CrMo, 40Cr, stainless steel. Can be adapted regarding customer requirements.

Blacking, galvanization, chroming, electrophoresis, color painting, ...

High frequency quenching heat treatment, hardened teeth, carbonizing, nitride, ...

Q: Are you trading company or manufacturer ?

A: Our group consists in 3 factories and 2 abroad sales corporations.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: How long is your delivery time ? What is your terms of payment ?

A: Generally it is 40-45 days. The time may vary depending on the product and the level of customization. For standard products, the payment is: 30% T/T in advance ,balance before shippment.

Q: What is the exact MOQ or price for your product ?

A: As an OEM company, we can provide and adapt our products to a wide range of needs.Thus, MOQ and price may greatly vary with size, material and further specifications; For instance, costly products or standard products will usually have a lower MOQ. Please contact us with all relevant details to get the most accurate quotation.

If you have another question, please feel free to contact us.

Address

Luotuo Industrial Area, Zhenhai District, Ningbo City, China